IQF vs Fresh Fruit in Hot Sauce: What Actually Matters

Most people comparing hot sauces focus on whether ingredients are "fresh" or "frozen"—but that's the wrong comparison. The real question is: Was the fruit picked ripe, or picked green? Because a mango frozen eight hours after ripening on the plant beats a "fresh" mango picked rock-hard two weeks ago, every single time.

By Timothy Kavarnos, Founder | Salamander Sauce Company

Quick Answer

In hot sauce, IQF (Individual Quick Frozen) fruit delivers better flavor than shipped "fresh" fruit because texture doesn't matter when everything gets blended, but ripeness does. IQF captures fruit at 14-18° Brix (maximum sweetness and flavor) within hours of harvest. "Fresh" tropical fruit is picked green at 10-12° Brix and ships for 1-3 weeks, never developing full flavor. For cooked applications, IQF wins on what actually matters: peak ripeness preservation.

The Romance vs. The Reality

Here's what most people do when evaluating hot sauce: They see "fresh fruit" on one label and assume it's better than anything frozen. They're judging the romance of the story, not the reality of the outcome.

But hot sauce isn't eaten raw. The fruit isn't served whole. Everything gets cooked and blended until smooth. So the question isn't "fresh or frozen?"—it's "which fruit had more flavor to begin with?"

What the Label Says vs. What Actually Matters

Let's eliminate the factors that sound important but actually have zero impact on your finished sauce:

| What People Worry About | Why It Doesn't Matter |

|---|---|

| Texture & Bite | It's pureed. Any texture advantage of fresh fruit disappears when you blend it to 200 microns. |

| "Fresh" on the Label | Tells you nothing about ripeness at harvest. Most "fresh" tropical fruit arrives picked green, 1-3 weeks after leaving the farm. |

| Romantic Sourcing Stories | Marketing fluff. Where it came from matters less than when it was picked and how flavor was preserved during transport. |

| Ingredient List Aesthetics | "Mango" looks the same whether it was ripe or green, fresh or frozen. The label doesn't tell the actual quality story. |

What the Fruit Delivers vs. What You're Told

Once you stop obsessing over inputs and focus on outcomes, the picture clarifies fast:

| What Really Impacts Your Sauce | Why It Matters |

|---|---|

| Peak Ripeness at Harvest | Sugar content (14-18° Brix for mango), aromatic compounds, and full flavor development only happen on the plant. After picking, fruit can't gain complexity—only lose it. |

| Volatile Flavor Compounds | The terpenes, esters, and lactones that make tropical fruit taste tropical degrade rapidly through oxidation and time. You either preserve them immediately (IQF) or lose them (shipping). |

| Consistency Batch to Batch | IQF delivers uniform quality year-round. Shipped fresh varies wildly by season, weather, shipping delays, and market availability. |

| Natural Sugar Concentration | Peak-ripe fruit eliminates the need for added sugars or syrups. The sweetness is authentic, not manufactured. |

"Stop judging the farm. Judge the flavor."

Peak Ripeness You Can Taste

The single biggest quality difference in hot sauce comes down to one question: Was the fruit allowed to ripen fully on the plant, or was it picked green to survive shipping?

The Sugar Density Reality

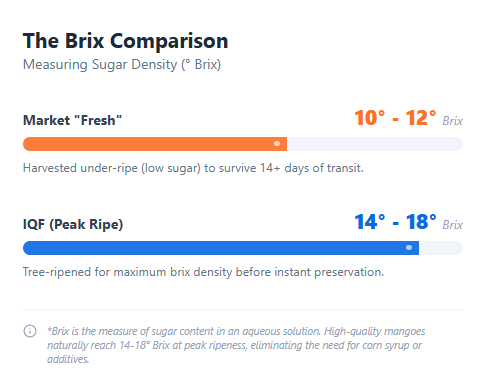

Brix measurement quantifies sugar content—the higher the number, the riper and more flavorful the fruit. Here's what actually makes it into different sauces:

| Fruit Type | Shipped "Fresh" (Green-Picked) | IQF (Ripe-Picked) | What You Taste |

|---|---|---|---|

| Mango | 10-12° Brix | 14-18° Brix | Starchy tartness vs. honey-like tropical sweetness |

| Pineapple | Minimal volatile esters | Peak aromatic compounds | Flat sweetness vs. vibrant tropical aroma |

| Papaya | 11-13° Brix | 14-16° Brix | Generic fruit flavor vs. complex tropical notes |

When fruit is picked at peak Brix, you don't need to compensate with cane sugar, agave, or corn syrup to simulate ripeness. The sweetness is already there—authentic and layered, not manufactured.

High-quality mangoes naturally reach 14-18° Brix at peak ripeness, eliminating the need for added sugars or syrups to create sweetness.

The Timeline That Changes Everything

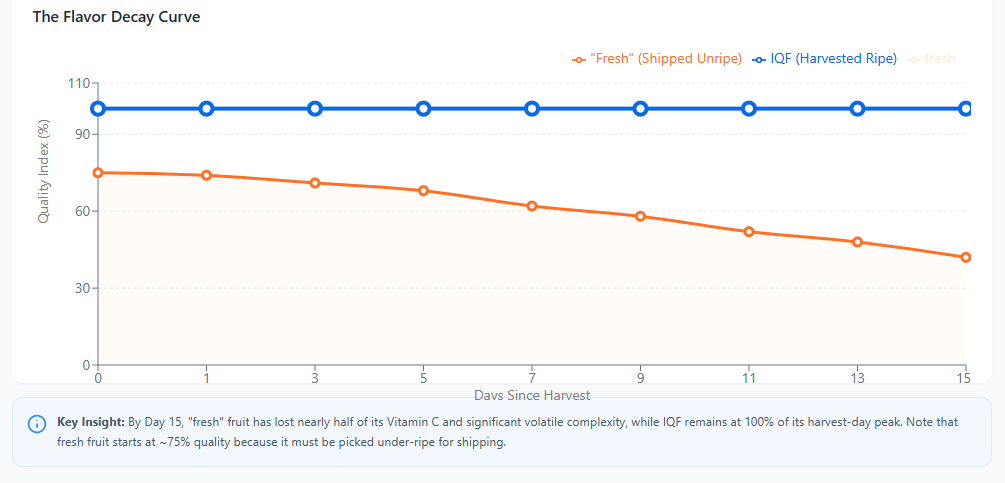

Flavor compounds start degrading the moment fruit is picked. Here's what the journey looks like for each method:

| Timeline Event | IQF Process | Shipped "Fresh" Process |

|---|---|---|

| Harvest | Picked at peak ripeness (maximum flavor/nutrients) | Picked green (for shipping durability) |

| Hour 8 | Blast frozen at -30°C, flavor locked | In transport, enzymatic reactions continuing |

| Day 3-7 | In cold storage, completely stable | Still in transit (ship/truck), nutrients degrading |

| Week 2-3 | Ready for use, peak quality maintained | Arrives at manufacturer, vitamin C already down 51%, volatile compounds diminished |

The difference is eight hours versus three weeks. In that window, "fresh" fruit loses nutrients, aromatics, and flavor complexity. IQF preserves everything at peak.

By Day 15, "fresh" fruit has lost nearly half of its vitamin C and significant volatile complexity, while IQF remains at 100% of its harvest-day peak.

Try the Sauce Built on Peak Ripeness

Eight tropical fruits frozen at maximum flavor. No added sugars. Just ripe fruit at its best.

Shop Tropical SauceThe "Inside the Bottle" Breakdown

Here's what typical hot sauce manufacturers do when fruit lacks flavor, compared to what becomes possible when you start with peak-ripe fruit:

| Ingredient/Element | Typical Tropical Sauce (Shipped Fresh) | Salamander Tropical (IQF Peak-Ripe) |

|---|---|---|

| Fruit Quality | Picked green, shipped for weeks, low Brix | Picked ripe, frozen in 8 hours, peak Brix (14-18°) |

| Added Sugars | Cane sugar, agave, or corn syrup (to compensate for bland fruit) | None needed—natural fruit sugars at peak |

| Vinegar/Acid | High volume to mask fruit flavor deficiency | Minimal—fruit flavor stands on its own |

| Texture/Body | Xanthan gum, modified starch (simulated body) | Real fruit fiber creates natural body |

| Color | Muted or artificially boosted | Naturally vibrant from carotenoids preserved by rapid freezing |

| Sodium | 110-200mg (needed to make bland fruit "pop") | 25mg per serving (high flavor density from ripe fruit means we don't need excessive salt) |

When ingredients are right, you don't need additives. The fruit provides sweetness, body, and color naturally—because it was actually ripe when it was preserved. And when fruit has that much natural flavor intensity, you don't need to pile on salt to make the sauce "pop."

The Professional Standard at Home

High-end restaurant chefs have known this for decades: Properly frozen produce often has better flavor than "fresh" that's been shipped across continents.

When Per Se needs out-of-season peaches for their winter menu, they use IQF fruit frozen at peak ripeness in August. When The French Laundry creates tropical desserts in January, the mango and pineapple come from IQF suppliers who freeze fruit within hours of harvest. When Alain Ducasse specifies ingredients for his restaurant group, individual quick freezing is the standard for maintaining quality across seasons.

These aren't shortcuts. They're quality decisions. The same principle that makes IQF standard in professional kitchens applies to hot sauce: Peak ripeness preserved immediately beats under-ripe produce shipped slowly, every single time.

Why Don't More Brands Talk About This?

Because "frozen" sounds less premium than "fresh" to most consumers—even though the opposite is often true. Brands face a choice: Use inferior ingredients and lean into the "fresh" label, or use superior ingredients and educate about why IQF actually delivers better flavor.

Most brands choose silence. They use IQF fruit (it's cheaper, more consistent, and higher quality) but don't mention it because they assume consumers won't understand.

We assume you're smarter than that.

"If it's good enough for Michelin kitchens, it's the right choice for your pantry."

The Cost-Per-Flavor Reality

On paper, IQF tropical fruit might look more expensive per pound than shipped "fresh." But that comparison ignores yield loss, prep waste, and quality consistency.

The Yield Math

Fresh tropical fruit arrives with skin, pits, stems, and damaged portions. IQF arrives ready to use:

- Fresh mango: 45-55% usable flesh after peeling, pitting, trimming

- IQF mango chunks: 100% usable—already peeled, pitted, cut

- Fresh pineapple: 50-60% yield after coring, peeling, trimming eyes

- IQF pineapple pieces: 100% usable—pre-portioned and ready

When you account for actual usable product, IQF often costs the same or less per serving—while delivering 4-6° Brix higher sugar content and volatile compounds that shipped fresh fruit never had.

You aren't paying for pits and peels; you're paying for 100% peak-ripe flavor.

Consistency Is Worth Money

Shipped fresh varies wildly by season. January mango tastes different from August mango. Quality control becomes nearly impossible.

IQF delivers the same flavor profile January to December. Same Brix level. Same aromatic compounds. Same color. When you're making sauce in small batches, consistency isn't optional—it's the entire point.

Experience Consistent Peak-Ripe Flavor

Three profiles. All habanero-based. Same quality bottle after bottle, month after month.

Shop All Three SaucesHonesty Tastes Better

You're not just buying heat when you choose hot sauce. You're buying someone's decisions about quality, transparency, and what matters.

Most hot sauce brands won't tell you where their tropical fruit comes from or how it's processed. They lean on vague "real fruit" language and hope you don't ask questions. They bet that "fresh" sounds better than explaining why IQF actually delivers superior flavor.

We chose a different path: Explain the craft. Trust that people care about outcomes more than marketing labels. Use the same professional-grade approach that high-end restaurants rely on, then tell you exactly why.

The Sustainability Angle

IQF reduces food waste by 30-50% compared to fresh processing. There's no trim waste, no spoilage from shipping delays, no quality variation requiring secondary selection. Every piece of fruit that gets frozen at peak ripeness makes it into sauce.

Shipped fresh means loss at every stage: Damage in transit, over-ripening before use, prep waste from skins and pits, portions discarded for quality inconsistency. When you add it up, you're throwing away nearly half of what you paid for.

Using ingredients responsibly means using them completely. IQF makes that possible.

The Permission to Choose Based on Results

If you want to buy a marketing label that sounds romantic, look for "fresh."

If you want to buy the flavor of fruit that was actually allowed to ripen on the plant—captured at maximum Brix, preserved at peak aromatic compound development, delivered with no added sugars because none were needed—look for brands willing to explain their process.

In December, you can't get peak-season tropical fruit flavor from anything shipped fresh. The seasons don't work that way. But you can get it from fruit that was frozen at its best moment in August and preserved perfectly since.

That's not a compromise. That's craft.

Frequently Asked Questions

Doesn't "fresh" always mean better quality?

Not for tropical fruit shipped thousands of miles. "Fresh" tells you it wasn't frozen—it doesn't tell you when it was picked or how long it traveled. For tropical fruits like mango and pineapple, "fresh" typically means picked green (10-12° Brix) and shipped for 1-3 weeks. IQF means picked at peak ripeness (14-18° Brix) and frozen within 8 hours. The frozen fruit has more flavor because it was actually ripe when preserved.

Does freezing damage the flavor compounds?

The opposite. Rapid IQF freezing at -30°C to -40°C preserves volatile flavor compounds (terpenes, esters, lactones) that degrade during shipping. Studies show that properly frozen fruit can be MORE flavorful than shipped "fresh" because the aromatics are locked in immediately rather than oxidizing over weeks. The key is speed—IQF creates microscopic ice crystals that don't rupture cell walls, while slow freezing creates destructive large crystals.

Why doesn't texture matter in hot sauce?

Because hot sauce is cooked and blended to a smooth consistency. Any textural difference between fresh and frozen fruit disappears when you puree everything to 200 microns. Texture matters for eating fruit raw—where the crisp bite of fresh mango is superior. But for cooked applications where final texture comes from blending, not raw fruit structure, the ripeness and flavor compounds matter far more than cell wall integrity.

Don't frozen fruits have added preservatives?

No. IQF fruit is just fruit—frozen rapidly with nothing added. The freezing itself is the preservation method. There's no need for sodium, sulfites, or other preservatives when you freeze fruit at -18°C. This is a common misconception—nearly 50% of consumers incorrectly believe frozen produce contains high sodium or preservatives. It doesn't. It's just frozen fruit, often cleaner than "fresh" fruit treated with ripening gases during transport.

Is IQF fruit more expensive than fresh?

Not per usable pound. Fresh tropical fruit has 45-55% waste (skins, pits, damaged portions), while IQF arrives 100% usable—already peeled, pitted, and portioned. When you account for yield loss, labor costs, and quality consistency, IQF often costs the same or less than fresh while delivering 4-6° Brix higher sugar content. You're paying for more flavor per dollar, not less.

Can I tell the difference in the finished sauce?

Yes—IQF-based sauce has more tropical fruit flavor because the fruit was actually ripe. Sauces made with shipped "fresh" tropical fruit often compensate for bland fruit by adding cane sugar, corn syrup, or agave to simulate sweetness. They also tend to use higher vinegar levels to mask the lack of fruit flavor. When fruit starts at 14-18° Brix (IQF) instead of 10-12° Brix (shipped fresh), you don't need to fake the sweetness—it's authentically there.

Why Salamander Wins

- •Peak Brix: 14-18° natural sugar density—no added sugars needed

- •8-Hour Lock: Flavor frozen at the source, not degraded over weeks of shipping

- •Zero Fillers: No xanthan gum, no corn syrup, just 25mg sodium per serving

Ready to taste peak ripeness?

Eight tropical fruits frozen at their best moment. No added sugars, no xanthan gum, no compromises. Just ripe fruit, habanero heat, and nearly two decades of the same process.

Shop Salamander SauceAbout Timothy Kavarnos

Timothy founded Salamander Sauce after years working New York restaurants—front of house and kitchen, describing dishes, pairing wines, tasting with chefs, learning what makes people light up. That experience shaped his approach: sauce that works with food, not against it. Brooklyn-based, still tasting every batch.

Salamander Sauce Company. Born in Brooklyn, made in New York's Hudson Valley. All natural, low sodium, clean label.